BalcoDeck® - Loads distribution and anchoring-principles

INTRODUCTION

BalcoDeck® is a fully freestanding, non-invasive decking and balustrade system designed for rooftop and terrace applications where preserving waterproof membranes and structural integrity is essential. This document serves as a technical-educational guide for architects, specifiers, installers, technical teams, and customers.

Rather than focusing on project-specific calculations, this guide explains the principles we apply in every installation. It walks the reader through the challenges posed by wind loads and outlines how BalcoDeck® is designed to safely resist those forces using a variety of strategies. We aim to convey our philosophy and methodology in a clear, trustworthy way, without overwhelming detail.

APPLICABLE STANDARDS:

List the standards used:

- BS EN 1991-1-4:2005 + A1:2010 – Wind Actions

- UK National Annex to BS EN 1991-1-4

- BS EN 1990:2002 – Basis of Structural Design

- BS 6180:2011 – Barriers in and about buildings (for balustrades)

WIND LOAD CHALLENGES

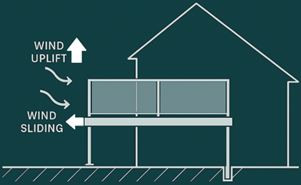

Wind affects freestanding rooftop or balcony decking structures through complex aerodynamic interactions that produce two dominant types of force:

- Uplift (Vertical Suction) – When wind flows over and around a horizontal surface such as a deck, a pressure differential is created. The air pressure underneath the deck is often higher than the pressure above it, resulting in a lifting or suction force. This uplift can act on decking boards, substructure, and even the pedestals, attempting to pull the entire assembly away from the surface. This effect is intensified at roof corners and edges, where wind turbulence and separation are greatest.

- Sliding (Lateral Pressure) – Wind acting on vertical components such as balustrades, privacy screens, or fascia panels exerts horizontal pressure. This force transfers into the decking platform as a shear load, potentially causing the entire deck to shift or slide laterally. The taller and more exposed the balustrade or screen, the greater the lateral force it produces.

These forces are not uniform and can fluctuate based on many site-specific variables, including:

- Building height – Taller buildings experience higher wind speeds and pressures at roof level due to reduced shielding.

- Terrain exposure – Open terrain (e.g., coastal or rural settings) exposes the deck to stronger, more consistent winds compared to urban or sheltered areas.

- Deck location on the roof – Decks at corners or roof edges are more susceptible to uplift and suction forces due to wind turbulence and pressure peaks.

- Deck openness – A fully open deck with no surrounding walls or obstructions is more vulnerable to wind uplift and pressure than one enclosed on multiple sides.

- Balustrade configuration – Balustrades with Privacy screen increases the surface area exposed to wind, resulting in greater lateral loading.

At BalcoDeck®, we always approach these challenges using a conservative, risk-averse design philosophy. We assume worst-case scenarios—such as maximum exposure, minimal shielding, and elevated height—to ensure the system performs reliably across all conditions. Even in less demanding environments, this strategy builds resilience into the design and avoids underestimating the effects of wind over time. The objective is simple: create a system that remains stable, compliant, and safe without relying on guesswork or marginal calculations.

SURFACE TYPES & MEMBRANE COMPATIBILITY

BalcoDeck® is typically installed on flat roof systems with waterproof membranes. These membranes vary significantly in their structure, adhesion characteristics, and load-bearing capability, all of which affect the performance of adhesive anchorage. Below is an overview of the most common roof membranes in UK homes and how they relate to BalcoDeck® installations:

1. GRP (Glass-Reinforced Plastic) / Fibreglass Roofs

GRP roofs are formed by laying glass matting and resin onto a timber substrate, creating a seamless, rigid finish. Once sanded and primed, they offer an excellent substrate for polyurethane adhesives like Sikaflex®-11 FC+ used with aluminium pedestals.

- Strengths:

- Rigid and seamless finish; very durable (20–30+ years).

- Resistant to foot traffic, UV, and standing water.

- Can be easily repaired or refinished.

- Risks: Surface must be sanded and primed; avoid glossy, unprepared topcoats.

- Suitability: Ideal for aluminium decking pedestals and balustrade baseplates.

- Impact on Wind/Uplift:

- Excellent adhesion base for PU adhesives (e.g., Sikaflex-11 FC+).

- When primed and sanded, can achieve high uplift resistance

- Strong lateral load performance

- Well-suited for adhered decking and balustrade baseplates.

2. Liquid-Applied Membranes (PU, PMMA, Polyurea)

These membranes cure into a seamless, elastic layer. Their chemical compatibility with PU adhesives makes them highly suitable for bonding aluminium pedestals.

- Strengths: Seamless, adaptable, fully bonded to substrate (no uplift air pockets).

- Risks: Substrate must be dry, clean, and structurally bonded.

- Suitability: Excellent—particularly for aluminium decking systems on terraces and refurbishment projects.

- Impact on Wind/Uplift:

- Highly resistant when well-bonded.

- Vulnerable if substrate is not well-prepared—delamination risk under suction.

- Reinforcement mesh may be added for structural strength.

3. Bituminous (Torch-On Felt – SBS/APP)

These traditional felt systems are common on older buildings. With good preparation (cleaning, priming), they accept adhesive bonding of aluminium pedestals, though performance depends on condition.

- Strengths:

- Durable (lifespan ~20–30 years).

- Good puncture resistance.

- Effective seal when well-applied.

- Risks: Aged or oxidised bitumen reduces bond strength. Separation layers may be needed.

- Suitability: Acceptable if reinforced and in good condition.

- Impact on Wind/Uplift:

- Relies on full adhesion to the substrate for resistance.

- Poor workmanship or aged bitumen can lead to peeling and uplift.

- Edges and terminations must be mechanically fixed or weighted to resist edge suction.

4. PVC Single Ply Membranes

PVC membranes are installed using adhesive, mechanical fixing, or ballast. Due to low surface energy, they show poor adhesion to PU adhesives even with primers.

- Strengths: Durable seams; useful in mechanically fixed systems.

- Risks: Requires specialist primers and manufacturer approval for use with aluminium pedestals.

- Suitability: Use with caution—prefer mechanical restraint or perimeter bracing.

- Impact on Wind/Uplift:

- Mechanically fixed systems rely on perimeter and field fasteners to resist uplift.

- Ballasted systems require heavy covering (e.g., pavers, gravel) to resist wind suction.

5. TPO (Thermoplastic Polyolefin) Membranes

TPO membranes, like PVC, present bonding challenges due to low surface energy. Specific primers are required, and compatibility with aluminium pedestal adhesive systems must be verified.

- Strengths: UV-stable, heat-weldable.

- Risks: Inconsistent bonding reliability without verified systems.

- Suitability: Only if approved by membrane supplier and used with mechanical perimeter restraint.

- Impact on Wind/Uplift:

- Mechanically fixed systems rely on perimeter and field fasteners to resist uplift.

- Ballasted systems require heavy covering (e.g., pavers, gravel) to resist wind suction.

6. EPDM Rubber Membranes

EPDM is flexible and durable but highly resistant to bonding with standard PU adhesives. It is generally unsuitable for adhesive-based anchoring of aluminium decking pedestals.

- Strengths:

- Long life (40+ years), UV and ozone resistant.

- Minimal seams (fewer weak points).

- Risks: Very poor adhesive compatibility. High peel risk under uplift.

- Suitability: Not recommended for aluminium pedestal systems.

- Impact on Wind/Uplift:

- Must be fully adhered or ballasted.

- Excellent flexibility under wind loads—can stretch without tearing.

- Perimeter detailing critical to prevent peeling under suction.

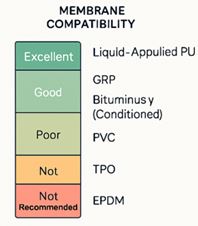

COMPATIBILITY TABLE:

|

Roof Membrane Type |

Compatibility |

Recommended Adhesive |

Surface Prep Needed |

Load-Bearing? |

Use for Adhesive Pedestals? |

Uplift Resistance |

Lateral Load Impact |

Common in |

|

GRP (Fibreglass Roof) |

Good |

Sikaflex-11 FC+, Primer-204 |

Light sanding + Primer-204 |

Yes |

Yes |

Very High |

Medium to high |

Extensions, dormers, balconies |

|

Liquid-Applied PU (e.g. Sikalastic, Kemperol) |

Excellent |

Sikaflex-11 FC+, 521 UV |

Clean + degrease (no primer) |

Yes |

Ideal |

High (if bonded) |

Medium |

Terraces, balconies |

|

Bituminous (Torch-On Felt, APP/SBS) |

Good |

Sikaflex-11 FC+, Primer-600 |

Clean + prime with Sika Primer-600 |

Moderate |

Yes, if in good condition |

Moderate |

Low |

Older flats, refurb |

|

PVC Single Ply |

Poor |

Sikaflex-552 + PVC primer |

Must use Sika PVC primer |

No |

Use with caution |

High |

Low to Medium |

Premium roofs |

|

TPO Single Ply |

Poor |

Sikaflex-554 + TPO primer |

Must use Sika TPO primer |

No |

Use only if approved by membrane supplier |

High |

Low to Medium |

Premium roofs |

|

EPDM Rubber |

Very Poor |

Generally, not suitable |

Requires special EPDM primers |

No |

Not recommended |

High |

Low |

Modern homes |

NOTE: If the roof membrane is not adequately bonded to the structural deck or exhibits insufficient tensile and shear strength, the adhesive connection between the pedestal and membrane may fail in peel or shear. This could lead to:

- Loss of uplift resistance, causing dislodgement of the decking system during wind events

- Loss of lateral stability, especially in cases where balustrades are fixed to the deck and transfer significant in-plane wind loads

Such failure modes are not governed by the adhesive strength alone but by the composite bond system, which includes membrane performance. Therefore, site verification or manufacturer certification of membrane strength is required prior to installation.

OUR ANCHORAGE PHILOSOPHY

We use a combination of non-invasive techniques to create a stable and code-compliant system. These methods are used individually or in combination depending on project conditions.

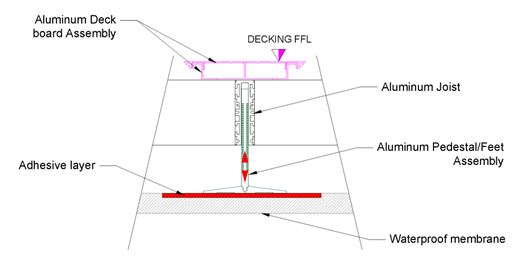

1. Adhesive Bonding (Primary Anchorage Method)

We use high-performance polyurethane adhesives (such as Sikaflex®-11 FC+) to bond the aluminum pedestals directly to the membrane surface. This method provides:

- Resistance to uplift through tensile adhesion

- Resistance to sliding through shear bonding

- Preservation of membrane integrity (no mechanical penetration)

Adhesive bonding is reliable, provided the surface is compatible and properly prepared. We work with different types of membranes and match them to the appropriate adhesive and primer, if needed.

The adhesive’s strength is more than sufficient to resist typical uplift and lateral loads when applied correctly. We allow for generous safety factors in design.

Exploded Decking Assembly View

2. Ballasting (Supplementary Weight)

Where additional downward force is needed, we use non-structural ballast such as concrete slabs, planters, or hidden weights. Ballasting increases the overall system weight to resist wind uplift.

- We evenly distribute ballast to avoid point loads on the membrane.

- Typical requirements are modest: around 10–12 kg/m² additional mass is often sufficient.

- We never exceed structural loading limits for roofs.

Ballasting works well in combination with adhesive bonding and helps improve frictional performance too.

3. Frictional Resistance

Every BalcoDeck® installation also benefits from passive friction between the pedestal base and the membrane. This opposes lateral sliding forces.

- On standard membrane surfaces, we assume a conservative coefficient of friction (μ) of ~0.3.

- With the use of rubber interface pads (EPDM or SBR), this can be increased to 0.5–0.6.

Frictional resistance is particularly helpful for resisting sliding loads acting on the balustrade. While not relied upon alone, it reduces demand on other anchoring elements.

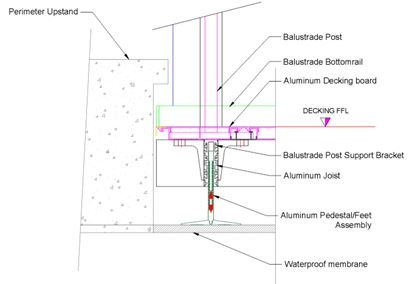

4. Perimeter Engagement

We often position the decking in close contact with existing parapet walls, upstands, or facade elements. This provides natural bracing and lateral resistance.

- Close engagement (<10 mm) helps contain movement

- Deck framing can be shaped to follow perimeter geometry

Perimeter engagement enhances overall system stability, especially under lateral loads. It is a simple but effective design element.

Edge Detailing Illustrations

5. Optional Mechanical Fixing (Where Permitted)

In select cases, we may fix parts of the deck or balustrade into perimeter walls or upstands using approved stainless-steel fixings. This is typically done only when allowed by the building design and waterproofing system.

- Mechanical fixings are helpful at exposed corners or where adhesive compatibility is poor

- Fixings are always designed to be corrosion-resistant and membrane-safe

- This approach adds redundancy and peace of mind

PUTTING IT ALL TOGETHER: SYSTEM STRATEGY

We never rely on a single anchorage method. Instead, we combine multiple layers of resistance to achieve stability:

|

Challenge |

Primary Approach |

Supporting Measures |

|

Uplift (Vertical) |

Adhesive bonding + system weight |

Ballasting, perimeter engagement |

|

Sliding (Lateral) |

Friction + adhesive shear bonding |

Perimeter engagement, optional fixing |

|

Balustrade Loads |

Structural design + perimeter |

Adhesive + optional mechanical restraint |

This layered strategy ensures that even if one measure underperforms, the system as a whole remains safe and stable.

CONCLUSION

BalcoDeck® has been engineered from the ground up to address the real-world challenges of rooftop installations:

- Non-invasive anchorage for membrane compatibility

- Modular aluminum structure for lightweight strength

- Smart layout options that adapt to perimeter conditions

- Adhesive bonding proven in wind-loaded environments

Our testing, conservative design philosophy, and flexible installation practices give confidence that each system can resist uplift and sliding without compromising the roof.

We understand that each rooftop is different. That’s why BalcoDeck® offers adaptable, proven strategies that combine strength, compliance, and ease of installation across a wide range of building types.

If you need assistance designing or specifying a BalcoDeck® system for a particular application, our technical team is happy to help.