Glass balustrades vs. plastics

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

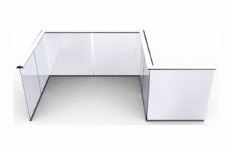

To price your balustrade requirement first choose the shape most similar to yours

Toughened Glass

Toughened glass is used as safety glass in various applications, such as low-level glazing, glazing in and around doors, overhead installations, and large areas of glazing. Its purpose is to prevent injuries resulting from accidental glass breakage.

Toughened glass is significantly stronger than regular glass, with a strength that can be up to five times greater. This means that it requires a much greater force to break. Additionally, when it does break, it shatters into small, less dangerous pieces.

Glass balustrades

Glass balustrades offer a sleek and glamorous alternative to more traditional materials like wood or stone. They provide a sense of lightness and airiness to balconies, staircases, and outdoor walkways. It's important to ensure that balustrade construction adheres to applicable regulations and standards. In the UK, glass balustrades are typically constructed using toughened glass, also known as tempered glass.

How is glass toughened

TThe technique used to create toughened glass involves heating glass objects beyond the annealing point of 600 degrees Celsius (1112 degrees Fahrenheit). The degree to which it is heated determines the varying grades of "toughening," resulting in toughened glass with two to six times the tensile strength of annealed glass. After heating, the glass is rapidly cooled on the outside using air blowers, typically by jets of cool air. This cooling process solidifies the outer layers while keeping the interior molten and fluid, creating the distinct layers within the glass. The energy trapped within the glass is what causes it to break into small fragments.

Impact resistance

Because of its layering, the surface of toughened glass is more resistant to impact. The same thrown object that would create a single hole in a pane of annealed glass would likely bounce off a comparable pane of toughened glass. The downside is that, due to the increased tensile strength of toughened glass, it is more likely to shatter completely when subjected to sufficient force. This can be a security concern, as breaching a toughened glass pane leaves no glass shards to deter entry. Additionally, toughened glass is more expensive to produce due to the additional cooling step required for the outer layer. Interestingly, it also has a softer surface that is more prone to scratches.

Physical Properties of toughened glass

Toughened glass is physically and thermally stronger than regular glass. The greater contraction of the inner layer during manufacturing induces compressive stresses on the glass surface, which are counterbalanced by tensile stresses in the body of the glass. It is this compressive stress that enhances the strength of toughened glass. This is because any surface flaws tend to be closed by the retained compressive forces, while the core layer remains relatively free of defects that could initiate cracks. However, the toughened glass surface is not as hard as annealed glass, making it slightly more susceptible to scratching. To mitigate this, manufacturers often apply various coatings and/or laminates to the glass surface.

Polycarbonate options

Polycarbonate sheeting is a building material commonly used as a substitute for glass in various applications. It is composed of thermoplastic composites and typically offers greater flexibility and shatter resistance compared to acrylics or plexiglass. The sheets are available in various thicknesses, ranging from 2mm to several centimetres.

This versatile material finds application as a glass alternative in doors and windows. It is also widely used in shower and pool enclosures, as well as on balconies and in greenhouses. Polycarbonate sheets are commonly utilized in sporting areas to protect spectators from flying balls or hockey pucks. Additionally, they are employed in the production of compact discs and eyeglass lenses.

Uses

Polycarbonate sheeting offers a wide range of options for installers and designers when it comes to its utilization. It can be securely fastened using screws and can be paired with specialized support poles designed for larger sheets. Additionally, it can be joined with other materials using epoxy or silicone, and it can even be welded if needed. Silicone sealant is commonly applied to seal or caulk

Primary advantages

One of the key advantages of polycarbonate sheeting is its excellent strength-to-weight ratio. In comparison to glass, it is significantly lighter while maintaining high resistance against shattering and damage. This shatter resistance makes polycarbonate sheeting a much safer alternative to glass. Additionally, it acts as an effective sound barrier and aids in controlling UV-light infiltration. Furthermore, its notable flexibility allows for easy shaping of each sheet according to desired specifications.

Visibility and light transmittance

Compared to other composite plastic sheeting products, polycarbonate sheeting is generally more expensive. It can also be susceptible to damage or failure when exposed to high temperatures. Like other plastic sheet goods, polycarbonate sheeting may acquire surface scratches from various factors. While some scratches can be eliminated using special polishes or cleaning products, others may be permanent. Continuous scratching over time can result in a dull appearance, reduced visibility, and diminished light transmittance.

For applications exposed to weathering or UV radiation, a special surface treatment is necessary. This can involve a coating to improve abrasion resistance or a coextrusion process for enhanced weathering resistance. Co-extrusion involves extruding multiple layers of material simultaneously. However, continuous exposure to sunlight and weather conditions makes polycarbonate sheeting less suitable for architectural usage in buildings, balconies, and balustrading due to clouding, susceptibility to scratching, and general weathering over time. Unfortunately, these effects cannot be rectified, and the only solution is replacement.

Cost

An additional consideration when using polycarbonate as a balustrade infill panel is the cost. On average, 10mm polycarbonate is three times more expensive than 10mm toughened glass. This cost factor is often the most influential when deciding on the material. However, when comparing it to 10mm curved toughened glass, the costs can balance out since polycarbonate can be manually shaped on-site to fit most radii and does not require a specific bending process.

In terms of Tensile Strength, polycarbonate is comparable to toughened glass. However, the Tensile Modulus of polycarbonate is approximately one-third of that possessed by toughened glass.

Summary

Polycarbonates find extensive use in bottling, medical applications, and eyeglasses. However, in the environmental context, they pose significant problems when improperly discarded as they are non-biodegradable. This contributes to issues of litter and overall untidiness in towns and cities. While polycarbonate is used as a glass substitute, there are several aspects that make it unpopular. Specifically, for balconies and balustrading, it is not a suitable alternative to toughened glass.

In contrast, toughened glass offers numerous advantages. By adding hydrophobic coatings to toughened glass, it becomes an even more fitting solution. Not only does it enhance aesthetics by keeping the glass clean without intervention, but it also reduces the introduction of detergents and cleaning chemical residues into the ecosystem.

Toughened glass stands as an ideal material for both decorative and practical architectural applications, both indoors and outdoors. It is easy to clean, durable, long-lasting, and fulfils the desire for light, bright, and airy spaces that are sought after today.