Railing and Balustrades Requirements

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

To price your balustrade requirement first choose the shape most similar to yours

What Materials are Allowed to be Used?

What Heights are Required for Balustrades?

Impact Testing on the Glass and Balustrade

Areas of Building Usage and the Loads that Apply

What Standards Do Balustrades Have to Follow?

The information provided below is sourced from two British standards: BS6180:2011 "Barriers in and about buildings - Code of practice," which pertains to the guidelines for balustrades in buildings which specifies load-related information. In this article, our aim is to simplify and explain some of the key principles and information found in these standards using layman's terms.

The majority of building regulation documents pertaining to balustrades, railings, and balconies are based on these standards.

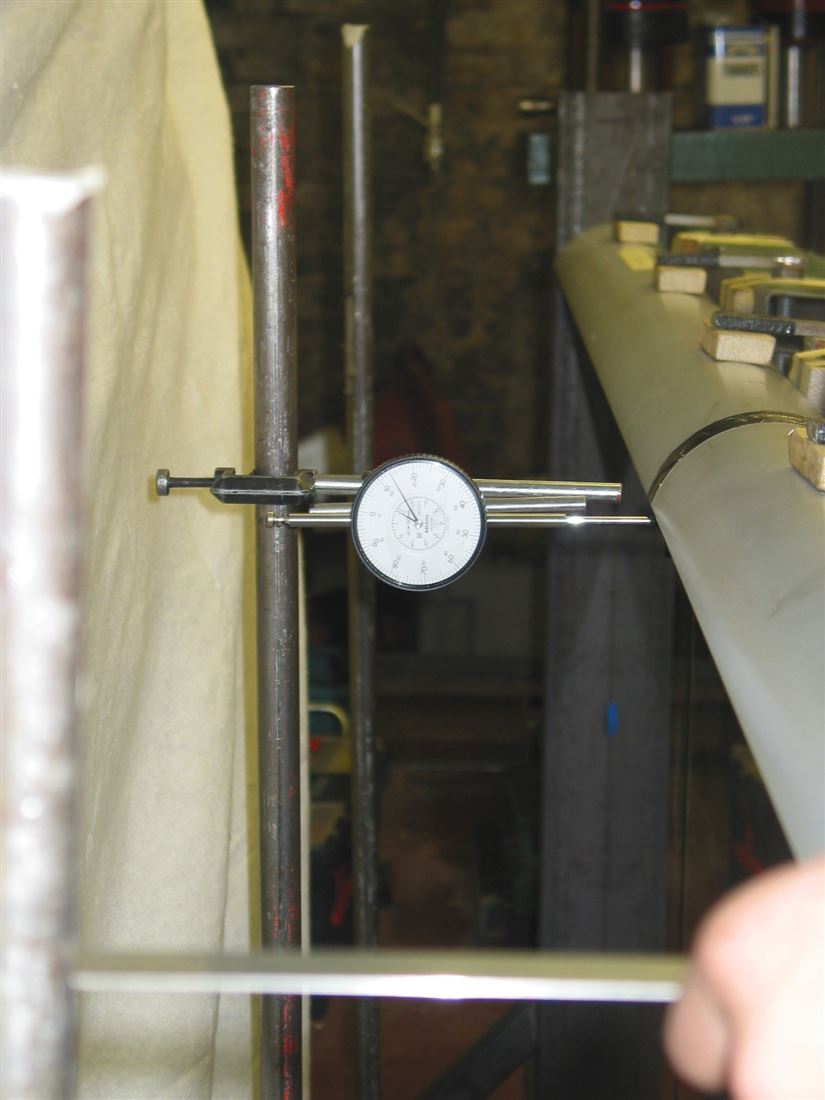

Deflection of balustrade under load

What Materials are Allowed?

There are no inherent limitations on the materials that can be used for balustrade structures. However, it is important that the chosen material possesses certain characteristics:

- Rigidity and strength to withstand pressure without bending, buckling, or breaking.

- Durability and suitability for the specific area of application.

- Plastics are generally not utilized for balustrade structures. Instead, metallic elements such as steel, stainless steel, or aluminium are commonly preferred. Wood has also been a popular choice, but it requires consideration for maintenance.

In some cases, the balustrade structure itself serves as the barrier, such as with bars or perforated metal panels. Additionally, in modern construction, glass is often used as infill panels, and in the case of structural glass, it actually acts as the barrier.

What Types of Glass can be Used?

When utilizing glass for balustrades, it is mandatory to use what is referred to as safety glass. Safety glass can be categorized into two types: (a) toughened glass, also known as tempered glass, or (b) laminated glass.

Toughened Glass

Toughening or tempering is a process that involves subjecting the glass to high temperatures of approximately 700 degrees Celsius and rapidly cooling it through quenching. This quenching process, which typically takes about one minute, results in the formation of a strong outer layer on both sides of the glass, while creating internal tension within the core. As a result, toughened glass becomes approximately four times stronger and more resistant to impacts compared to regular float glass.

Why is it Called ‘Safety Glass’?

You may wonder why this type of glass is referred to as "safety glass." The reason is that toughened glass, when broken, does not form large pieces or sharp shards. Instead, it "breaks safely" and shatters into numerous small fragments, which are much less hazardous and pose a lower risk of injury.

Laminated Glass

a combination of both. When subjected to conformity tests, laminated safety glass is permitted to break upon impact but must prevent the impacting object from penetrating the panel.

In the United Kingdom, toughened glass is primarily used, although there is a growing trend towards the use of laminated and toughened glass, especially in high-rise buildings. Conversely, in Europe, only laminated glass is allowed, and the use of single pane toughened glass is prohibited on balustrades.

The thickness and type of glass used vary and depend on factors such as the area requiring protection, the required impact class (which has several categories for safety glass), and the size of each individual pane used. More detailed information on this topic will be provided in the section relating to loadings.

|

|

What Heights are Required for Balustrades?

For internal railings or balustrades within a single-family dwelling, the required height is 0.9m from the "datum" (which is defined as the height or point you can stand on) to the top of the handrail. In the case of external balcony or terrace areas, the required height is 1.1m from the datum to the top of the handrail.

The handrail height for stairs, whether internal or external and for all uses, is set at 0.9m from the datum.

Impact Testing on the Glass and Balustrade

What loadings and forces are railings/balustrades designed to withstand, and how are they applied, tested, or calculated?

Load Types:

The loads are measured in kN/m (kilo Newton meter), which can be understood as roughly 100kg (220lb) of pressure per metre length. For instance, if it is stated that there is a load of 1.0kN/m, it would be approximately equivalent to a person weighing 100kg exerting their full weight on a one-metre length.

There are two primary loads that must be considered:

(a) Horizontal loading on the handrail

(b) Loading on the infill

The horizontal loading on the handrail is referred to as a "uniformly distributed line load" or UDL. This means that the load should be calculated in a manner that allows for even distribution of pressure along the entire length of the element, rather than summing up the load applied at a single point.

The load on the infill, whether it is glass, metal, or another material, is tested and calculated in two distinct ways: a distributed load and a "point load." This means that the infill of the railing, balustrade, or barrier must be capable of withstanding both an even pressure distributed over its surface and a concentrated “point” pressure applied at specific points.

The loads are either tested or calculated, and the maximum deflection under pressure must not exceed 25mm.

|

|

Areas of Building Usage and the Loads that Apply

You can divide regulations into these basic areas:

Domestic & Residential (Single Family Home), Internal Stairs/Landings Etc.

In this case, the handrail must be able to withstand a pressure of 0.36kN/m. However, for external balconies and in light office areas that are not prone to overcrowding, this requirement is doubled to 0.74kN/m. To put it into perspective, this can be likened to having an average person weighing 75kg exerting their full body weight on every metre of the balcony.

Public Areas Such as Retail Areas, Bars and Restaurants

The handrail must be capable of withstanding a pressure of 1.5 kN/m. However, in areas such as malls, discotheques, and other crowded spaces, this requirement is dramatically doubled to 3.0 kN/m.

Regarding the loads applied to the glass or infill panels in these areas, we will focus on the more severe of the two loads, which is the concentrated point load.

Point Load for Domestic & Residential (Single Family Home) Internal Stairs/Landings Etc.

0.25kN/m. For external balconies and in light office areas non susceptible to overcrowding 0.5kN/m.

Point Load for Public Areas

In all public areas, including retail spaces, malls, discotheques, crowded areas, bars, and restaurants, the point load for the glass barrier must be able to withstand 1.5kN/m.

When considering glass barriers, another important factor to consider is the impact resistance of the glass. For balcony areas wider than 1.5m, a minimum thickness of 10mm glass should be used to ensure adequate strength and safety.

Uniformly distributed load on the handrail

Residential Balconies in London

Residential Loading Requirements on Balconies

|

|