Structural Glass Balustrades - Types and Methods

Glass Balustrades | Juliet Balconies | Galleries | Articles | Case Studies

To price your balustrade requirement first choose the shape most similar to yours

Why is a balustrade named a "structural glass balustrade"? And what sets it apart from other types of balustrades? The answer is simple, yet there are various methods to implement this type of solution.

What is a Structural Glass Balustrade?

A structural glass balustrade refers to a balustrade where the glass serves not only as an infill panel but also as the actual structure. It is also known as a frameless glass balustrade or a cantilevered glass balustrade.

The concept is based on two engineering principles:

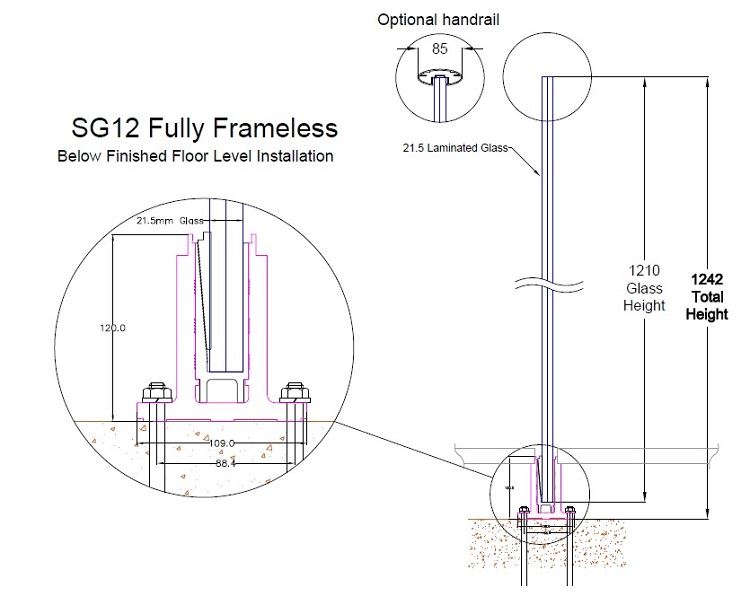

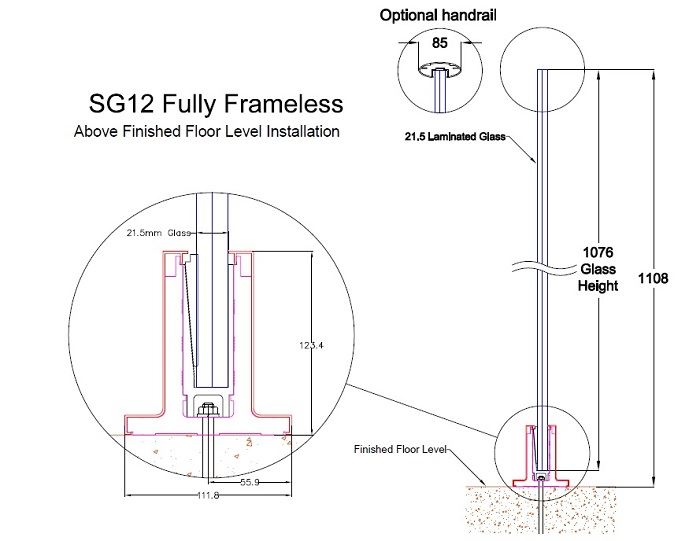

- A strong base channel capable of housing/holding thick glass and resisting the load from the glass.

- Glass panels with a thickness and strength that can resist and withstand bending moments and loads.

Since the revision of BS6180 in 2011, it is now possible to choose whether or not to have a handrail. The handrail, placed on top of the glass, ties the glasses together, adding sturdiness and solidity to the entire structure. It must also be able to withstand the required load in case one of the glass panels breaks.

If you want to have no handrail over the glass, then laminated glass must be used, with a thickness that can withstand the loads, and will remain in place even if one side breaks.

Fully Frameless Balustrade Section

The Base Section of the Structural Glass Balustrade

The base section, also known as the "shoe profile" in some systems, requires careful design attention. The basic idea is a strong "U" channel made from two RSAs back-to-back or using specially designed aluminium extrusions. The glass is fixed in place using epoxy (two-part component glue) or sometimes a cement-type material.

In recent years, there has been innovation in these systems, allowing the use of base profiles with pressure-screwed clamps or hammered-in wedges, eliminating the need for cement or epoxy glue. This innovation saves labour and avoids the messy process of pouring epoxy into a small channel.

The base profiles can be fixed to the balcony structure using various materials such as steel, concrete, or others. These base profiles and their fixings need to be purpose-designed for each site to ensure they can withstand the large loads transferred from the glass panel.

The Glass Panel

While most balconies or balustrade systems can utilize 10mm toughened (tempered) glass, structural glass balustrades require a much stronger glass panel.

For structural systems with a handrail, a minimum thickness of 15mm toughened glass must be used, even for residential properties. In high-loading areas like public spaces, bars, restaurants, discothèques, and malls, thicker glass panels are necessary. Cases may require the use of 21.5mm or even 25mm toughened laminated glass panels. Balconette's SG12 Structural Glass Balustrade system comes with 21.5mm toughened laminated glass as the standard option. But can also be supplied with 25.5mm thick glass for public areas.

Due to the thickness of the glass required and the iron content in standard float glass, structural glass balustrades may exhibit a greenish tint more than regular glass balustrade systems. This can be reduced by using "low iron" glass panels, although they are more expensive.

Can laminated glass be used on this type of balustrade?

Yes, laminated glass can be used, but it is crucial to consider the appropriate thickness. 17.5mm laminated toughened glass is not as strong as 15mm toughened glass. We would not recommend use of any laminated glass for frameless balustrades that is less than 21.5mm.

Specific calculations must be undertaken to determine the correct makeup of the laminated panel.

Heat Soak Test

Although not mandatory, it is recommended to subject the glass panels used in structural glass balustrades to a "heat soak test." This test eliminates 99% of spontaneous breakage cases that can occur with toughened glass. In structural glass balustrades, spontaneous breakage can be very dangerous and expensive to replace, which often outweighs the cost of conducting heat soak tests.

Weight and Self-Imposed Loads

When designing a structural glass balustrade, it is essential to consider the weight of the system and the load it imposes on the balcony or structure, in addition to any other load requirements. A typical structural glass balustrade using 21.5mm thick glass weighs around 60-65 kg per linear meter. Therefore, a ten-meter-long structural glass system can weigh over half a ton!

Handrails and Top Capping

Various handrails can be used with this type of balustrade, ranging from simple "U" cappings to elegant elliptical stainless steel or anodized aluminium handrails. It is important to select a handrail that not only looks aesthetically pleasing on top of the glass but also has the strength to bridge a gap in case one of the glass panels breaks.

Structural advice

Countless systems and methods exist for implementing structural glass balustrades, all based on the same fundamental principle of transferring the load through the glass to a sturdy base channel. Due to the detailed design requirements and variations in fixing methods from site to site, it is strongly advised to involve a structural engineer when selecting a system, fixing method, and glass.

Maintenance and Cleaning

Proper maintenance and cleaning are essential for keeping structural glass balustrades in pristine condition. Regular cleaning helps to maintain the transparency and aesthetics of the glass panels. It is recommended to protect the glass using a self-cleaning Glass coating such as BalcoNano ®. BalcoNano ® will reduce the cleaning cycle required and allow to clean the glass without use of any harsh chemicals that can damage the glass surface.

In coastal areas or locations prone to salt deposition, it is crucial to rinse the glass panels frequently with clean water to remove salt residues that can cause corrosion over time. Additionally, applying a protective coating or sealant to the glass surface can provide extra resistance against dirt, water spots, and staining.

Furthermore, it is advisable to inspect the base profiles and fixings periodically to ensure they remain secure and in good condition. Any signs of wear, damage, or corrosion should be addressed promptly to maintain the structural integrity of the balustrade.

Building Regulations and Safety Compliance

When installing a structural glass balustrade, it is important to adhere to local building regulations and safety standards. These regulations vary depending on the jurisdiction, and it is crucial to consult with local authorities or a qualified professional to ensure compliance.

Structural glass balustrades must meet specific criteria regarding load-bearing capacity, height requirements, and safety considerations. These regulations are in place to ensure the protection and well-being of individuals using the balustrade and to prevent accidents or structural failures.

By following the appropriate regulations and obtaining necessary permits or certifications, you can ensure that your structural glass balustrade meets the required safety standards and provides a secure environment for its users.

Conclusion

When properly designed, a balcony or terrace with an uninterrupted glass barrier, free from vertical metal elements, can be an exquisite balustrade solution. However, it's important to acknowledge that this option may not be suitable for every budget or site condition.

Structural glass balustrades present a contemporary and visually pleasing choice for residential and commercial spaces alike. By utilizing glass panels as both an infill and a structural component, these balustrades offer an unobstructed view, amplify natural light, and create a feeling of spaciousness.

To ensure the safety, longevity, and aesthetic appeal of structural glass balustrades, careful consideration must be given to design, material selection, and installation techniques. Taking into account factors such as base profiles, glass panel thickness, handrails, and involving a structural engineer will contribute to a balustrade system that not only meets regulatory standards but also exudes elegance and refinement.

Regular maintenance and cleaning of the glass are vital in preserving its transparency and overall appearance. By adhering to maintenance guidelines and complying with local building regulations, you can relish the beauty and functionality of your structural glass balustrade for many years to come.

In summary, structural glass balustrades offer a modern and alluring solution, but their suitability depends on various factors. By approaching their design and maintenance thoughtfully, you can achieve a remarkable balustrade system that enhances the aesthetics and functionality of your space.

A balcony or terrace with a limitless ability to have just glass as a barrier without the need for any vertical metal elements, does not suit every pocket or site conditions but when designed properly, is one of the more aesthetic balustrade solutions that exists.