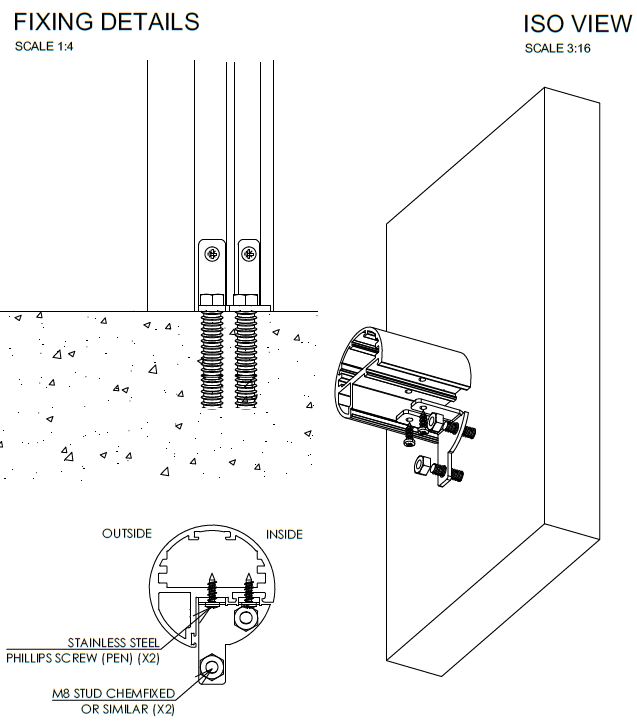

Hybrid® Orbit System Glass Balustrade - Technical Specifications

Tech Specs | Installation | Gallery | Projects | Reviews

Orbit system glass balustrade (circular handrail) drawings, structural calculations, technical materials specification and loading tests.

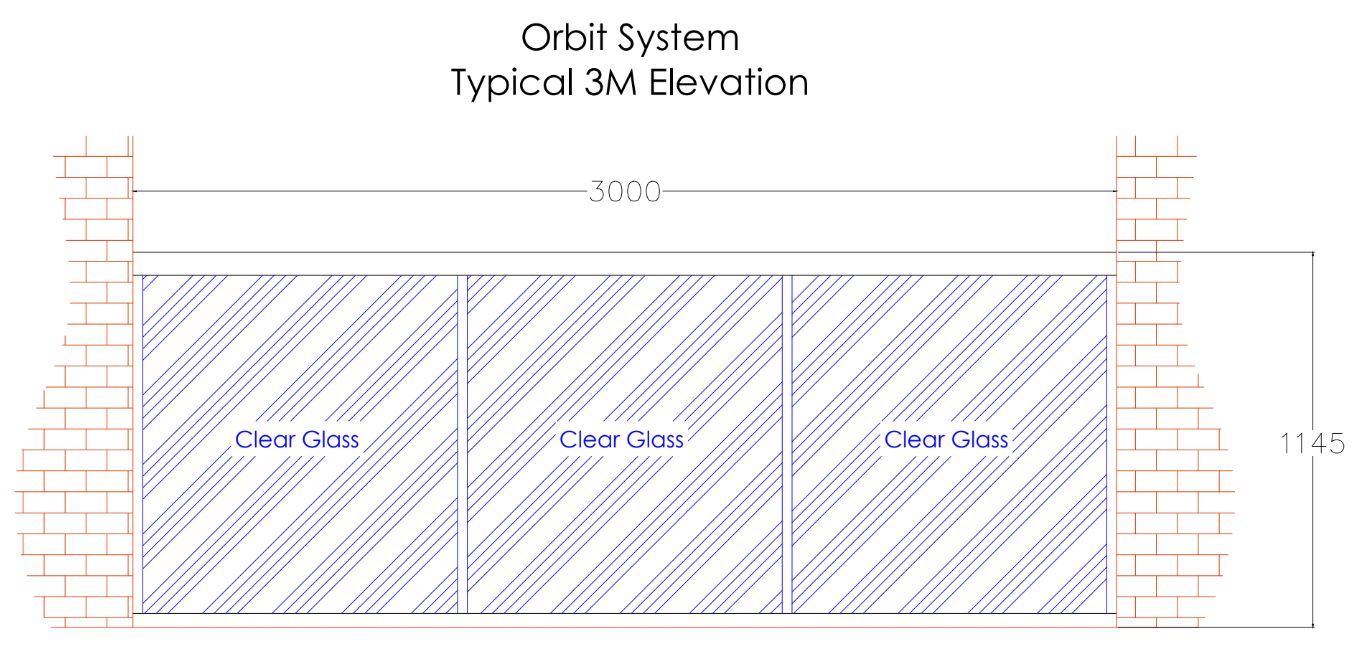

TYPICAL 3M ELEVATION

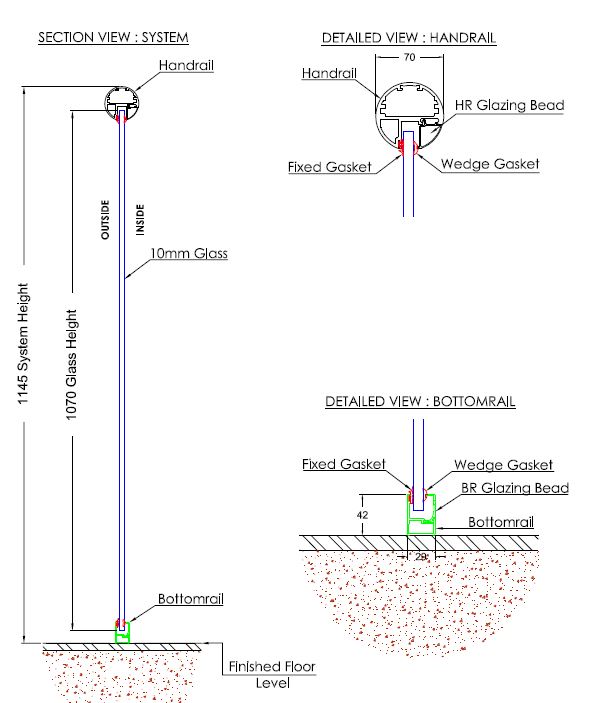

WALL BRACKET |

SECTION |

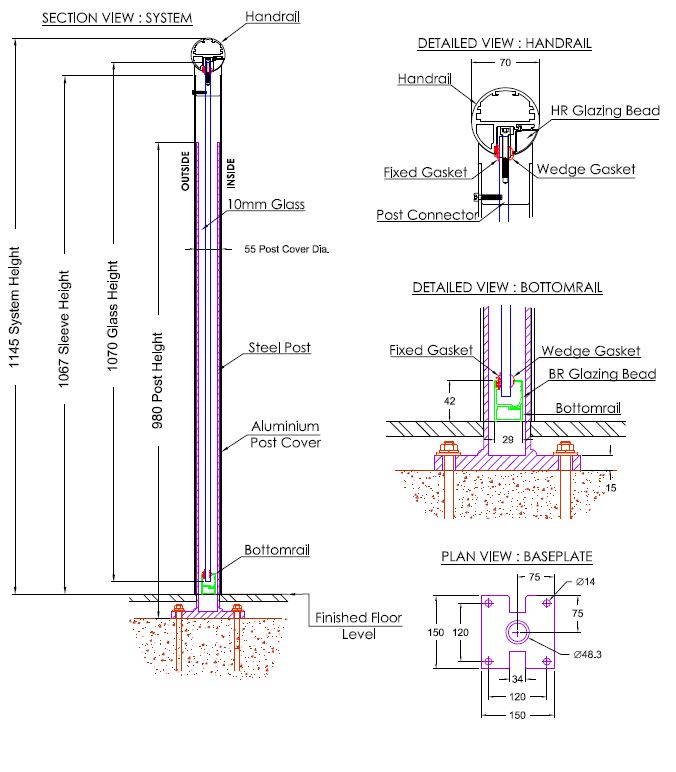

POST SECTION

Orbit Technical Materials Specification

Balustrade and base structure:

- 6063 T5 & 6063 T6 extruded aluminium profiles

Powder Coating or Anodising:

Colour options available for Hybrid Systems (Orbit & Aerofoil)

- 15 micron high-quality anodising in Matt Silver, Matt Bronze or "Royal Chrome" finish

- 60-100 micron Polyester powder coating in white colour

- 60-100 micron Polyester powder coating in RAL colour options available for large projects only.

Primary Insert Posts

- Galvanized Steel with 15mm thick base plates.

Gaskets:

- EPDM (ethylene-propylene rubber)

Glasses:

Glass available for Hybrid Systems (Orbit & Aerofoil)

- 10mm clear toughened

- 10mm satinised (opaque) toughened

- 10mm tinted toughened (Green, Grey or Bronze)

- All the above can be supplied with the BalcoNano ® self-cleaning coating.

Design Criteria

Permitted Loading:

Loading is taken from Table 2 of BS 6180:2011 Barriers in and about buildings – Code of practice

A copy of this table can viewed here: Table 2 Minimum horizontal imposed loads for parapets, barriers and balustrades.

Residential (Covers occupancy types i, ii, ii, iv, v, viii & ix shown in Table 2 above)

- Horizontal uniformly distributed line load (at 1.1m handrail height) - 0.74 kN/m

- Uniformly distributed load applied to the infill - 1.0 kN/m2

- A point load applied to part of the infill - 0.5 kN

Public (Covers occupancy types vi, vii, x & xiii shown in Table 2 above)

- Horizontal uniformly distributed line load (at 1.1m handrail height) - 1.5 kN/m

- Uniformly distributed load applied to the infill - 1.5 kN/m2

- A point load applied to part of the infill - 1.5 kN

NB: it is assumed that the wall/structure being fixed to can support the required loads.

Structural Calculations

The Structural calculations below are for each system type. There are calculation below for residential occupancies and also public areas as specified above in Table 2 Minimum horizontal imposed loads for parapets, barriers and balustrades.

LOADING TESTS

Balcony and Balustrading Systems in the UK must comply with BS6180, the loadings in BS6399 and building regulations.

The Systems have been load tested by independent engineering companies to test physically and in practice the ability of the systems to resist loadings.

The tests include; deflection under maximum load, loads uniformly distributed and point load tests. Both the handrails and glass infill panels were subjected to the testing. The testing confirmed that the systems meet and exceed the required criteria.

- Load testing Appendix A: pictures

- Point load testing on our balustrade system glass infill

- Uniformly distributed load testing on our balustrade system glass infill

- Introduction document for load tests

- Load testing on our balcony balustrade system